Sublimation Transfers

Easily transfer multi-colored, pattern, and photo-realistic designs with custom sublimation transfers. Our sublimation prints ready to press make it simple to create stunning, long-lasting designs. Sublimation utilizes special dyes that permanently bond with your fabric, ensuring that your sublimation transfers are breathable, durable, and resistant to fading.

Sublimation Sensation with Custom Sublimation Transfers

- Works on 100% PolyesterSublimated T-shirt printing, Mugs, Cups, Bags & more

- Vibrant or Soft ColorsWe can also match your custom colors

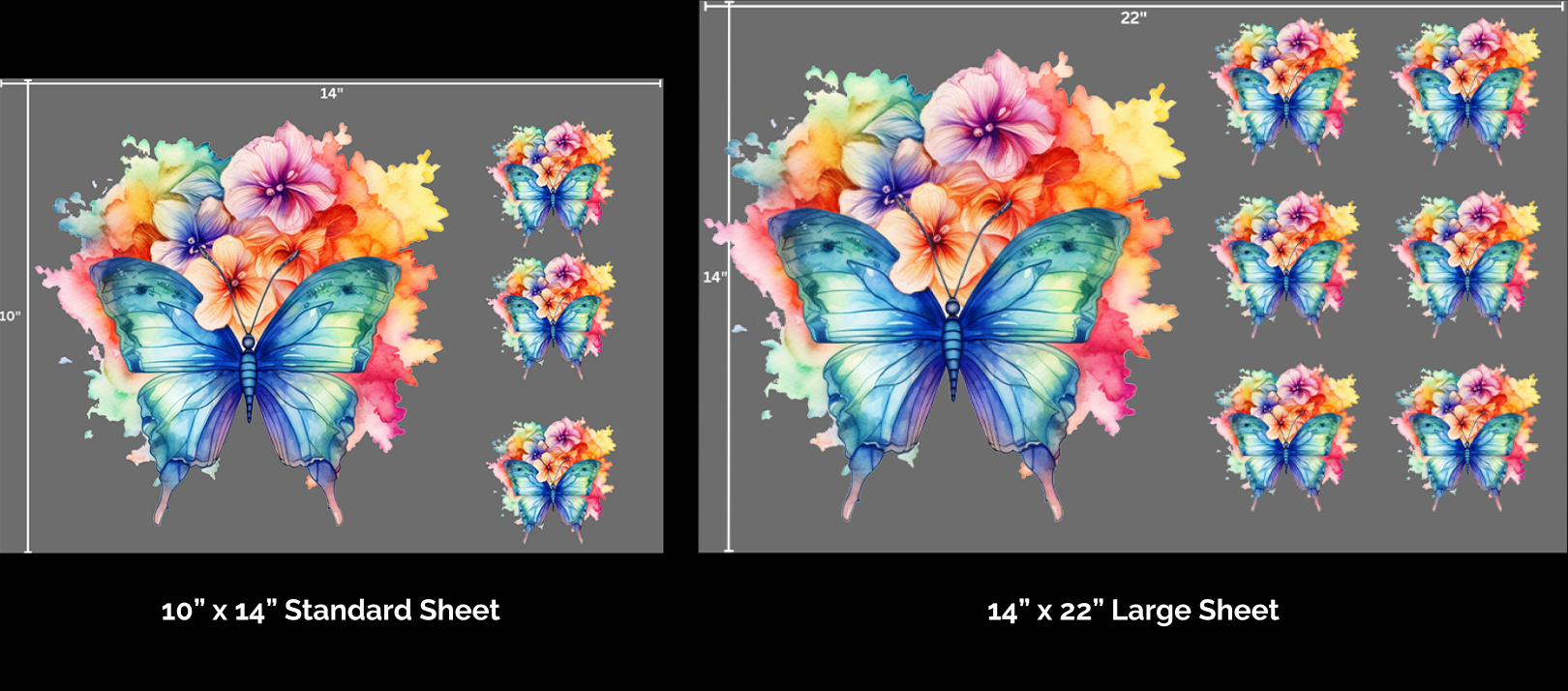

- Flexible Gang Sheet SizesWe offer 2 sheet sizes

- Softest Sublimation Transfers for 100% Polyester Sublimation dye penetrates and colors your white fabrics

- Low Gang Sheet MinimumsOrder as little as 10 Gang Sheets

- Fast Turn Around TimesShips in as little as 2 business days

- Heat Press Custom Transfers AvailableIdeal for personalized, high-quality results

Pricing: Affordable Sublimation Prints with Low Minimums – Ready to Press!

Discover high-quality sublimation transfers ready to press at competitive prices (priced not including $20 set up)! Whether you’re creating custom apparel, promotional items, or home decor, our vibrant sublimation transfers are designed to deliver stunning results with ease. Get started today and bring your creative visions to life!

Large Sheet – 14″ x 22″

| 10-23 | 24-35 | 36-49 | 50-99 | 100-299 | 300-499 | 500-999 |

|---|---|---|---|---|---|---|

| $2.81 | $2.55 | $2.34 | $2.16 | $2.01 | $1.87 | $1.75 |

Standard Sheet – 10″ x 14″

| 10-23 | 24-35 | 36-49 | 50-99 | 100-299 | 300-499 | 500-999 |

|---|---|---|---|---|---|---|

| $1.89 | $1.72 | $1.64 | $1.51 | $1.40 | $1.36 | $1.27 |

Maximize Your Savings with Gang Sheets

Looking for cost-effective wholesale sublimation printing services? Our gang sheets offer unbeatable value, allowing you to print multiple designs at once. Order as little as 10 gang sheets and enjoy vibrant, durable sublimation prints!

Application Instructions

Easy application process

![]()

Temperature

385°F – 400°F

![]()

Time

45-60 Seconds

![]()

Pressure

Medium

![]()

Peel

Warm

Artwork Specifications

How to prepare your print ready art file

File Formats

We accept a variety of file formats, including Illustrator, Photoshop, Corel Draw, PDF, EPS, and SVG files.Learn More

Printable area

Set your artboard dimensions and position your artwork within the printable area at your intended size.Learn More

Convert Fonts to Outline

Ensure all fonts are converted to outlines. Editable type may not display correctly, depending on the computer’s font library.Learn More

Check Image Details

To ensure clear printing of fine details, all smallest areas must meet the requirements provided below.Learn More

Frequently Asked Questions

We are here to help!

What are sublimation heat transfers?

Sublimation heat transfers are a printing process where a design is printed onto sublimation paper using special inks. When heated, these inks turn into gas and permeate the fibers of polyester materials, resulting in a vibrant, permanent print. This method is ideal for creating long-lasting designs on items like fabrics, mugs, and even specialty materials for sublimation to make stickers with durable, high-quality finishes.

Will sublimation transfers print on cotton fabric?

Sublimation is best suited for polyester materials. While it’s possible to use on cotton, the result may be faded and will likely wash out over time. For better results on cotton, consider other transfer methods.

What materials can be used with sublimation heat transfers?

Sublimation is most effective on polyester or polyester-blend fabrics. It can also be used on hard surfaces that have a special polymer coating, such as mugs, phone cases, and metal sheets.

Why do my sublimation prints look faded or washed out?

Faded prints can result from not using the correct temperature, pressure, or transfer time. Ensure you’re using the recommended settings for your specific substrate and that your sublimation inks and paper are of high quality.

How durable are sublimation print?

Sublimation transfers are known for their durability. Since the ink becomes part of the fabric, it’s resistant to fading, peeling, or cracking, even after multiple washes.

Why is there a ghosting effect on my transferred design?

Ghosting can occur if the transfer paper shifts during the pressing process. To prevent this, ensure the paper is securely taped or held in place. It’s best to use a teflon sheet to cover the transfer during the application process.

Can I use any heat press for sublimation transfers?

While many heat presses can be used for sublimation, it’s essential to choose one that provides consistent heat and pressure. This ensures the best possible transfer quality.

How should I wash garments with sublimation prints?

Turn the garment inside out and wash it in cold water using a mild detergent. Avoid using bleach or fabric softeners. Tumble dry on low or air dry to maintain the print’s vibrancy.

Are sublimation prints eco-friendly?

Sublimation printing is considered more eco-friendly than some other methods. The inks are water-based and don’t require any solvents. Additionally, there’s minimal waste since the design is printed directly onto the material.

What’s the difference between sublimation heat transfers and traditional heat transfers?

Traditional heat transfers involve applying a design on top of a fabric using adhesive or carrier film, which can sometimes be felt when touched. Custom sublimation transfers, on the other hand, embed the design into the fabric itself by turning the ink into gas that permeates the fibers. This results in a seamless feel, with the design becoming an integral part of the fabric, offering a more durable and vibrant print.

Related products

VIDEO TUTORIAL

VIDEO TUTORIAL

VIDEO TUTORIAL